Appleton HEP/ James Lichoulas Web Page

March 22, 2008

Dear Viewers:

I need your assistance, in saving, the existing, historically significant, Appleton Hydroelectric Project. The City of Lowell has seized my friend Jim Lichoulas’ defunct mill property and hydroplant. Jim is trying to re-instate his FERC license, L.P. No. P-09300. The City has intervened and wants to bulldoze under the property including the station. Please go to the Appleton HEP/Lichoulas web page located on the sidebar. Please read about this epic, David and Goliath, struggle between Jim and the City of Lowell. Jim is a visionary developer and the salt of the earth!! He needs our help. Appleton HEP-Jim Lichoulas <<< please click for Appleton's website.

See the "YOU Tube" link below for "rare action footage of the site" Lets make this sweetheart run again!!!!

I ask that you send a copy of my form e-mail or one of your own to the FERC and other suggested e-mail addresses in order to save the site!!

**** March 28th, 2008****

Jim's son has lent me this astonishing "You Tube" family movies of the Appleton Site when it was running!!!!!

http://www.youtube.com/watch?v=efZfa8w7VNg <<< please click

*****************************************************************

Appleton Mills was incorporated in 1826 with $500,000 in capital. Engineer Paul Moody constructed the mill buildings. Moody was the first engineer to incorporate leather belts and pulleys, as a substitute for heavy gearing, when he built the futuristic and pioneering Appleton Mill. The factory was located on the Lowell Canal System owned and operated by the Proprietors of the Locks and Canals on Merrimac River (PLCM). PLCM was incorporated on June 27, 1792. It took another 34 years, until 1830, for a dam to be constructed across the Merrimac River. Appleton’s textile machinery included 380 looms with 11,776 spindles. The original employees included 470 females and 65 males. By 1880, this had increased to 1,228 looms with 45,000 spindles. Its products included broadcloth, cotton, carpet and cassimere.

Appleton’s water power included a head of 13 feet with a gross horsepower of 725 HP. 750 HP, of supplemental steam power, provided backup during the low flow summer months. The original prime movers at Appleton were enormous breast wheels that were 30 feet in diameter, with a maximum efficiency of 60 %.

In 1832, the ancestor of the modern, radial flow, turbine was invented by two French Engineers, Claude Burdin (1790-1873) a professor at the Ecole des Mines at Saint Etienne and his student, Benoit Fourneyron (1802-1867). In 1833, the Societe de Encouragement pour le Industrie National, offered a prize to any person producing a large scale, commercial hydraulic turbine. Fourneyron won the prize, for his turbine design. This original Fourneyron design was used to replace the breast wheels at Appleton. The Fourneyron turbine was licensed to others to manufacture. In the early 1840s, James Francis and his assistant Uriah A. Boyden modified and patented improvements to the design of the Fourneyron Turbine. Uriah A. Boyden left Lowell in 1848. In 1849, he began to manufacture his turbine, at the Ames Manufacturing Company, on the Chicopee River. The Appleton wheels were replaced again with Boyden wheels in the early 1870s.

A final replacement, of the waterwheels, was effected in 1903, as a result of the design efforts, of Mr. John B. McCormack. Mr. McCormack came to Holyoke in 1877 and entered the shops of the Holyoke Machine Company. Here he perfected Francis’ turbine wheel. It took him about eleven years. While there, he brought out the "Hercules" wheel, which Mr. Emerson, the Director of the famous Holyoke Testing Flume, so highly commended.

The Appleton Mill was located between the upper, Hamilton Canal and the lower, Pawtucket canal. The drop between the canals was a regulated, essentially constant, 13 feet. Five penstocks conveyed water, to seven pressure cases, located in the basement of the mill. The pressure cases contained seven sets of 54 inch diameter Holyoke Machine Company, Hercules Turbines. The water than discharged, through four tailrace tunnels, into the Pawtucket Canal.

During the 1950s and 1960s, the textile industry, mostly collapsed, leaving the City of Lowell and its mill buildings to decay. The Appleton Mills Complex spanned both sides of Jackson Street. A young, progressive and inspired real estate developer, Mr. James Lichoulas purchased the entire Appleton Complex. He made a spectacular redevelopment, of the buildings, on the southeast side of Jackson Street. In the late 1970s and early 1980s, in response to the oil embargo of 1973, and helped by the revamped Federal Energy Regulatory Commission licensing procedure, Mr. Lichoulas again displayed his insight and forward thinking by taking the steps to license the Appleton Hydro facilities. He was a pioneer in the post 1978 FERC hydro licensing process and paved the way for others to apply for licenses. It took several years to complete the FERC license but finally, on July 18th, 1986, Jim had his FERC license in hand. He now had to rehabilitate one of the Holyoke Hercules installations to produce 346 kilowatts.

To give you an idea, of how incredible Jim is at thinking outside the box, I give you the following anecdote. At 13 feet of head, the 54 inch, McCormack Holyoke turbine produced 232 horsepower and turned at 82 RPM. Of course this was a camelback unit, consisting of two runners on a common shaft, so the entire unit produced 465 HP or 346 kilowatts. In order to connect it to the 1800 RPM generator, you need a 22:1 speed increaser The original millwrights solved the problem by installing a 22 foot diameter, cast iron, with wooden rim, pulley, on the turbine shaft and a one foot diameter pulley on the generator shaft. The pulleys had a 4 foot width and were set 45 feet apart. The pulleys were connected by an enormous leather belt. The drive pulley was so large that it revolved partially in the tailwater. In order to keep it dry, an enormous tin tub was built around the bottom of the pulley with a pump installed in the tub’s bottom. The pump discharged any leakage water, thus keeping the belt dry. A recommendation was given to Jim to discard this system and purchase a gearbox. When Jim got the $ 250,000 quote for the gearbox he decided to buy a new belt. But where do you get a new belt? No leather manufacturer in the U.S. would consider the possibility of making such a belt. Hey no problem!!! says Jim. He found a leather manufacturer in Ireland who would make the belt. He purchased a herd of cattle in Ireland. He had the cattle slaughtered, sold the meat and sent the hides to the tannery. Within two months, they made the new belt for Jim and sent it back to Lowell. Jim was able to get the belt for free in exchange for selling the prime rib!!!

During late 1986 and 1987, Jim hired David, Luke and Seth Wright, millwrights from Ware River Power Company. Jim and the Wrights rolled up their sleeves and went to work. They cleaned and polished and repaired the turbine, generator and switchgear. They put it back on line and it ran for about ten years. Around 1993, the turbine started to make thudding noises. An investigation showed that one of the 7000 pound runners was loose on its shaft. Several ideas were employed to repair the shaft insitu. These included drilling, tapping and installing giant set screws and several versions of epoxy coatings. The unit limped on for another four years. Finally, the trip hammer pounding of the runner against the shaft broke it. Astonishingly, this shaft was one piece, of eight inch stock, that was 49 feet long with no coupling between the runners.

Please remember, that at this time (1995), the power companies had been deregulated and the economy was going sour. The power sales rate, that Jim was being compensated for the sale of the generated power, had plummeted to $0.025/kilowatt-hour. In addition, Jim did not have the resources to repair the enormous Appleton Mill. The roofs started to leak and the mill building that housed the turbines was decaying. This resulted in legal machinations between the City of Lowell and Jim Lichoulas to repair the building. This is all well and good but you can not get blood from a stone. The current tax relief benefits and renewable energy credit incentives for historic buildings and hydro development did not exist. Jim kept applying to FERC, for extensions to the license, hoping for a turn of events, to make hydro more economical, so that he could redevelop the site. In the mean time, the City of Lowell took action, to take the property by eminent domain, and they did!! The ironic part is that they appraised the property for 13 million dollars. They then awarded Jim two million dollars, but kept a huge share for site cleanup and fines, because the buildings were in disrepair. What a raw deal!!! The City does not care about the hydro station. They are bulldozing the entire site, filling in the flumes and cutting up the equipment. They are going to construct a new building on the reprocessed lot. Note that the hydro station is postage size compared to the entire lot. It could easily stay and be incorporated into the new building as an addendum.

Jim is trying to save his license at FERC. The City has intervened at FERC. They say the station is not historically significant and does not produce enough power to bother with. What hubris!!!!! We are facing the destruction of our planet and when every source of green power counts and is being developed. Here is a wonderful source of power being twisted from the arms of a brilliant, creative pioneer of the hydropower renaissance!!! Jim Lichoulas deserves better and we all deserve better.

I have prepared the following form letter from the friends of Appleton Hydro. I ask that you cut and paste it into your e-mail browser and send to:

U.S. Senator Edward M. Kennedy

http://kennedy.senate.gov/senator/contact.cfm

Governor Duval Patrick

http://www.mass.gov/? pageID=gov3utilities&sid=Agov3&U=Agov3_contact_us

Federal Energy Regulatory Commission

The Honorable Kimberly D. Bose, Secretary

Federal Energy Commission

888 First Street, NE, Washington, DC 20426

and the FERC Commissioners

and the famous director of the New York Regional Office

Please sign our guest book by Cc: RLich1@aol.com on your e-mail.

We look forward to giving you a private tour of the site the next time your in Lowell visiting the Federal Historical District.

Mr. Fay

As I explained on the phone yesterday, to get your thoughts in the record, you need to efile or use the quick comment form at: http://www.ferc.gov/docs-filing/efiling.asp in P-9300. The Commission’s FERC Online Support team, which is included on this email, is available to help you with that process.

*******************************************************************

We, the friends of Appleton Hydroelectric, FERC license, L.P. No. P-09300, plead that the Federal Energy Regulatory Commission reinstate license number P-09300 to its original licensee, Mr. James Lichoulas. In this time of escalating gas and home heating oil prices, we find it astonishing, that this 346 kilowatt hydro project is being allowed to have its license rescinded and the site bull dozed under, for another office building. We think that Mr. Lichoulas should be rewarded for his years of enduring efforts to preserve the hydro license. We understand the trials and tribulations of being a small business man, the backbone of this country. It took great visionary efforts to originally rehabilitate and operate Appleton Hydro during the 1980s and 1990s. As a tax payer and voter, we plead that you give this matter additional scrutiny and re-instate Mr. Lichoulas FERC license. Please see www.frenchriverland.com and click on the Appleton Hydro/Lichoulas sidebar. Your kind consideration in this matter is greatly appreciated.

Sincerely,

>>>>your name and address<<<<<

*******************************************************************

Jim’s immediate plan is to put a new roof on the powerhouse and restore the equipment. He is applying to the Massachusetts Technology Collaborative for both RECs and grant money to restore the site. We have some 8 inch line shafting that we removed from the Collins Paper Company in Wilbraham, MA. We intend to remove the runners, press the runners off the broken shaft. Install the bad runner on the 62” Bullard turret lathe, bore out the runner hub and install it on the new shaft. We intend to make the new shaft in two pieces with solid couplings in between. (See the machine shop side bar)

Well that’s my story. Thank you for reading about Appleton’s and Mr. Jim Lichoulas’ plight. I hope you will help us.

Please peruse the following pictures, of the destruction, wrought upon the site, by the City of Lowell’s demolition team. Although these pictures are disturbing, we have rehabilitated worse sites!!!

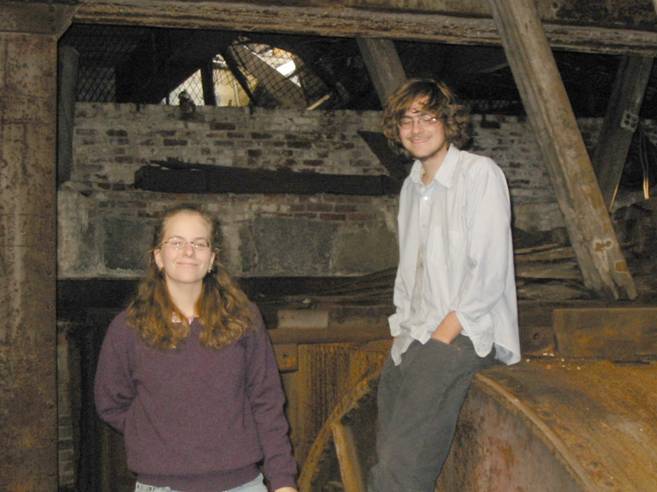

Will and Celeste at the entrance to the powerhouse.

A close up view of the entrance to the powerhouse.

A view of the pressure casing and the top of the Lombard Governor.

Will sitting on top of the Hercules pressure casing.

The remains of the Lombard Governor.

A view of the Bull Pulley. It is in the top of the picture. Jim and Dave painted the edge of the pulley in a patriotic red, white and blue motif.

Another view of the top of the Lombard Governor. Note the debris stream from the City’s wrecking crew. The round hole, in the brick wall, on the left was originally opened up to facilitate removal of the runners and main shaft.

Note the arc of the Bull Pulley in the center top of the picture.

David and Set Wright’s rebuild nameplate.

A view of the synchronous, salient pole generator.

More destruction of the hydro property by the City’s wrecking crew.