Jaffery Fire Protection Web Page

Davis Hobbs and I purchased the General Electric, synchronous, salient pole, horizontal, 150 kilowatt, 164 rpm generator from the sub basement of the Jaffery Fire Protection Company in Jaffery, N.H. The problem was that it was located in a sub basement next to the foundations of a reciprocating steam engine. In order to remove it, we had to bring it up two stories through rock maple floors. Then it had to be rolled across an enclosed pedestrian bridge between the two sides of the mill over the river. Then it had to be taken out through one of the mill windows!! The doorways were to low to slide the stator through. In order to successfully rig out the generator, we had to dismantle it and take it in five separate pieces, the stator, the rotor, the two bearing pedestals and the bed.

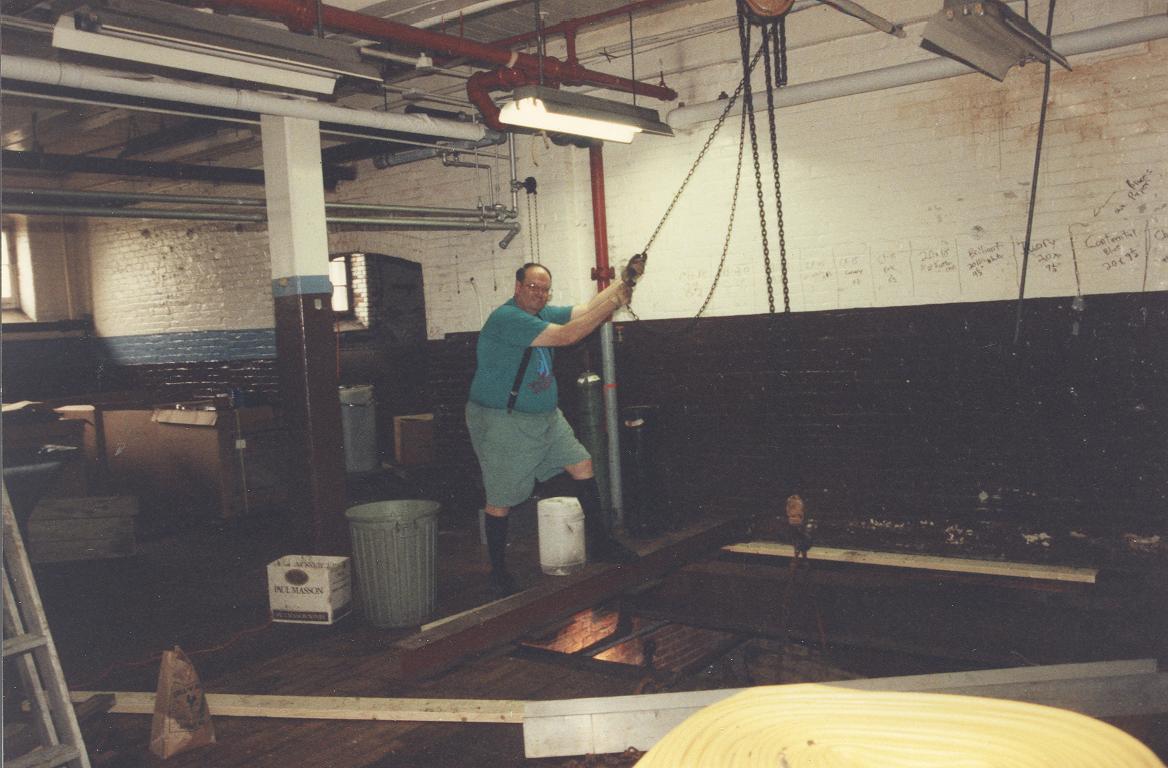

This was on day one and Davis is rolling in our tools and rigging.

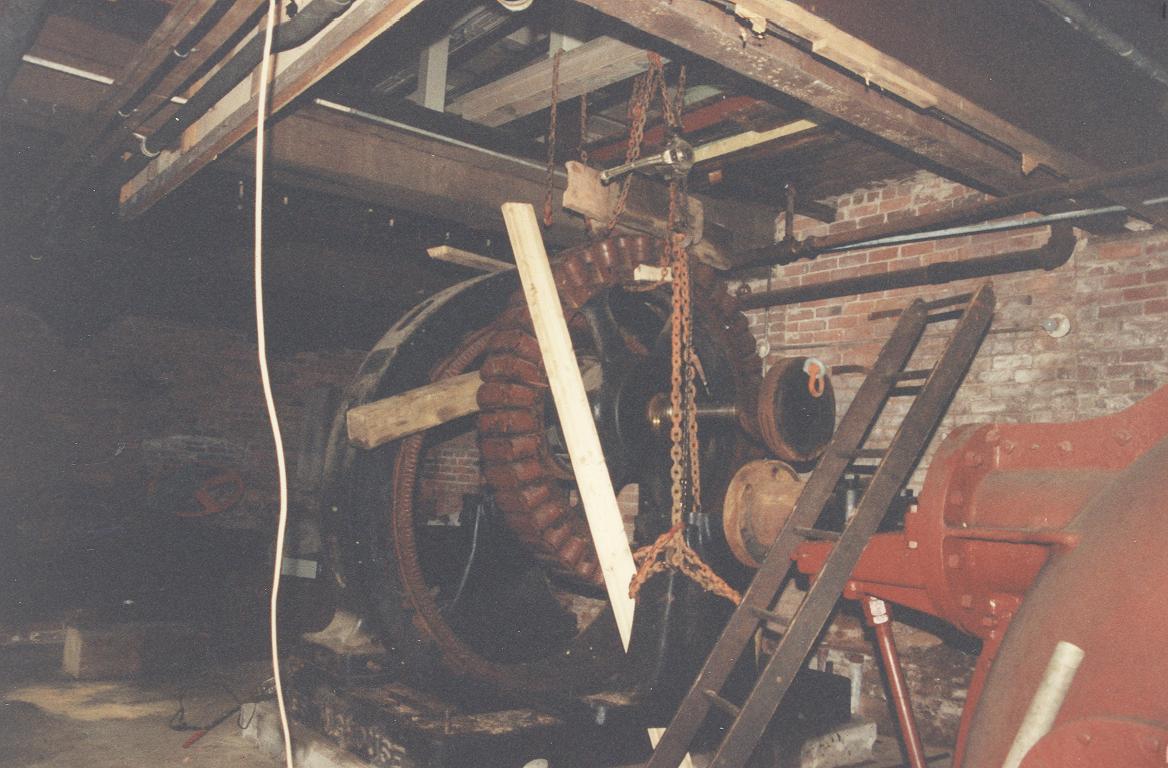

Here you can see the end of the Holyoke, Hercules, cylinder gate turbine that the generator was coupled to.

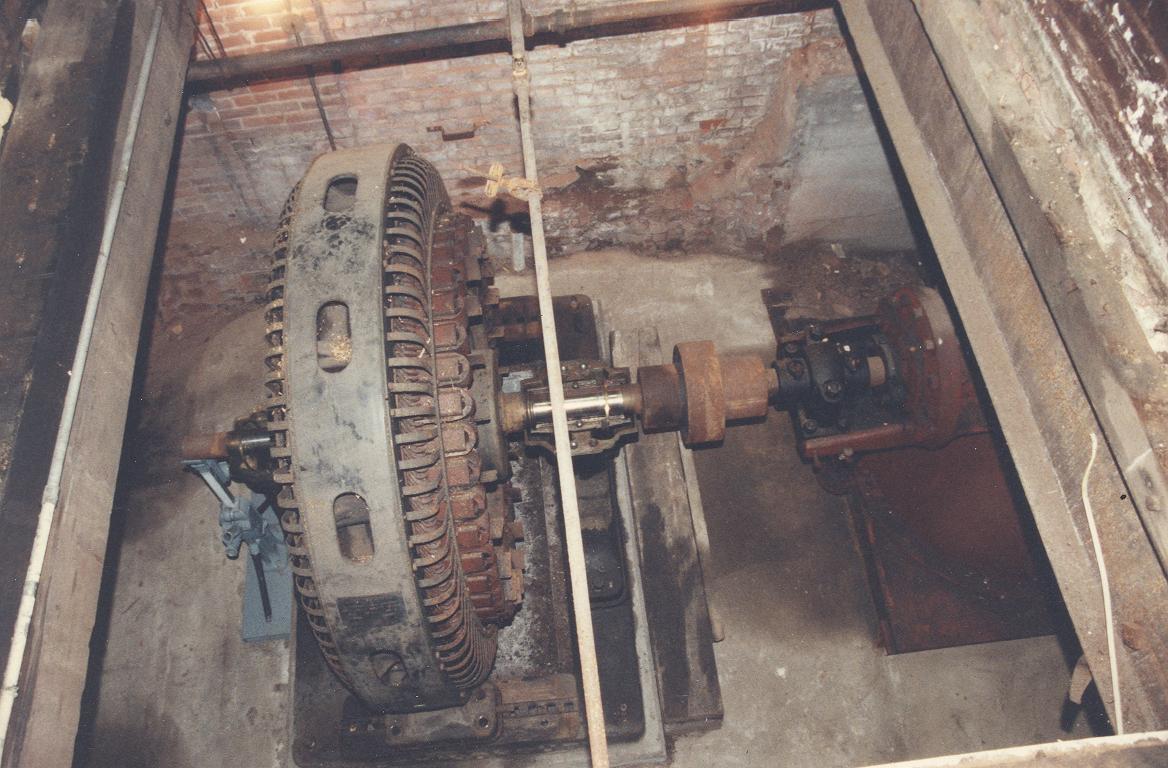

Here is a birds eye view of the generator in the hole we cut in the basement floor. The generator is still coupled to the turbine.

Russell McCord of Fort Wayne, Indiana is running the ten ton chainfall and pulling the rotor out of the cellar.

Here we have removed the bearing pedestals. We have rigged the rotor out of the stator and we are carefully lifting the rotor through the hatch we cut in the cellar floor.

The rotor disappearing through the hole in the basement floor.

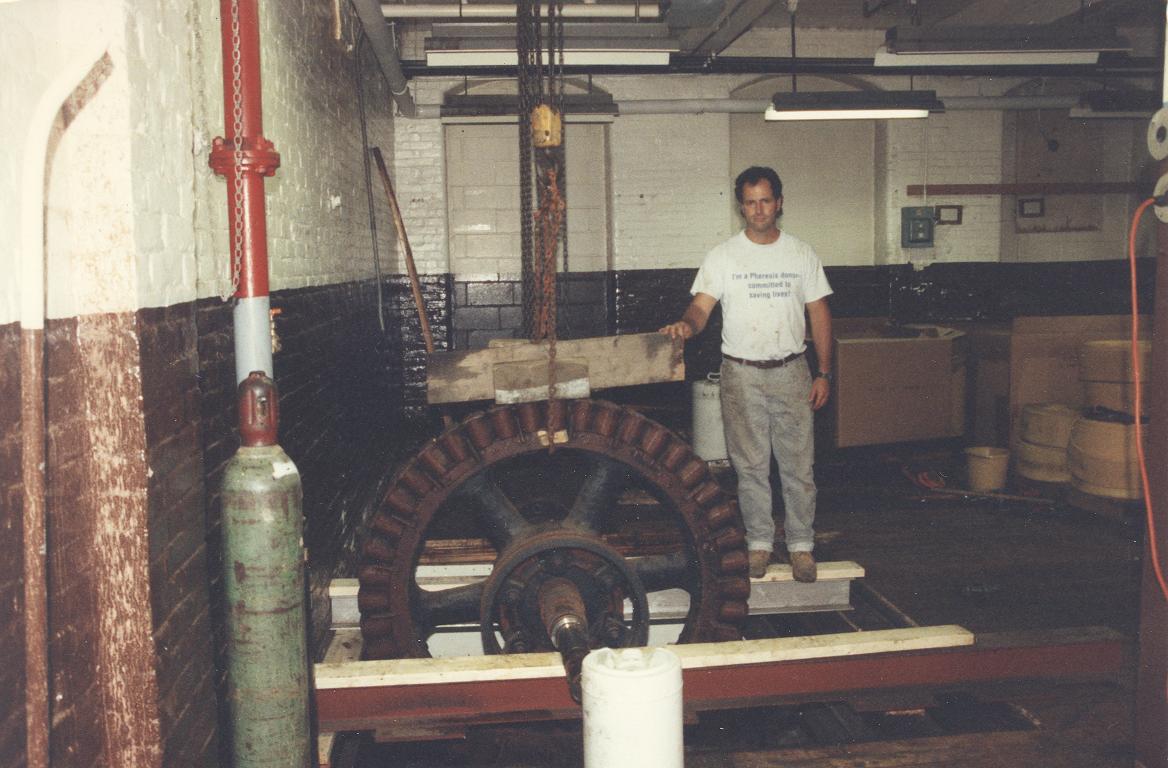

Here is the rotor coming through the second hatch we cut in the first floor. We have rested the rotor on small I-beams that we lined with 2x8s.

Another view of the rotor. Davis is getting ready to change out the rigging so that we can install cribbing beneath the shaft. We drilled a hole. with a 2 inch auger in the second story floor. We inserted an enourmous eyebolt up through the hole. We spanned the eye bolt with two short sections of I-beam. We slid a piece of heavy steel plate over the eyebolt and screwed the nut down. We then hung our chainfalls on a shackle that was through the eyebolt.

The rotor is on its cribbing. We placed caterpillar, machinery rollers beneath the cribbing and rolled the rotor out.

Another view of the cribbed up rotor.

A rare picture of me with my Lombard Log Hauler tee shirt on!! I was always the guy taking the pictures. Russell McCord was a great help. He was on one of his New England tours.

This is several weeks later and we have rigged the stator out of the sub basement. We moved it across the bridge. We are now taking the rotor out of one of the window openings. The stator is hanging on the crane boom. You can see the generator bed on the back of our cherry picker. All in a days work!!!! Several years later, we removed the turbine from the basement for a religious group in New York.