GOLDEN POND HYDRO PAGE

The facility is licensed by the Federal Energy Regulatory Commission. It is known as Golden Pond Hydro, FERC L.P. No. 5638 NH. It consists of a dam with adjacent powerhouse. The powerhouse contains one Leroy Somers, HydroLec, turbine generating set. It is mounted on a headwall and is fed by a 5 foot diameter penstock. The unit is a Model H9H 18 with automatically adjustable blade pitch. At a nominal head of 18 feet the unit produces 84 kilowatts. It drives an 84 kilowatt induction generator which is rated 3 phase, 60 hertz, 150 amps at 480 volts. The generator frame is a 405 T. It has 4 poles and spins at 1835 RPM. The power factor is 0.85. The water is shut off with a 60" butterfly valve.

The unit is controlled with a G.E. Fanuc Series 90-30 programmable logic controller. The 480 volts is stepped up through a transformer located adjacent to the power house to 13,800 volts. The unit is tyed into the Ashland Electric Light Company (AELC). Freshwater Hydro negotiating a power sales contract with AELC.

Freshwater Hydro (aka: Golden Pond Hydro) was the product of the genius of George Lagassa of Portsmouth, N.H. In 1981 Mr. Lagassa was looking for a site to rebuild. He found a dam on the Squam River at the site of the former Ashland Paper Company. The paper company was anandoned in the late 1960's and later burned to the ground. This dam is downstream from Squam Lake which was made famous in the Katherine Hepburn, Peter and Jane Fonda movie "On Golden Pond".

Will Fay has just finished clearing the debris from the crest of the spillway using a chainsaw

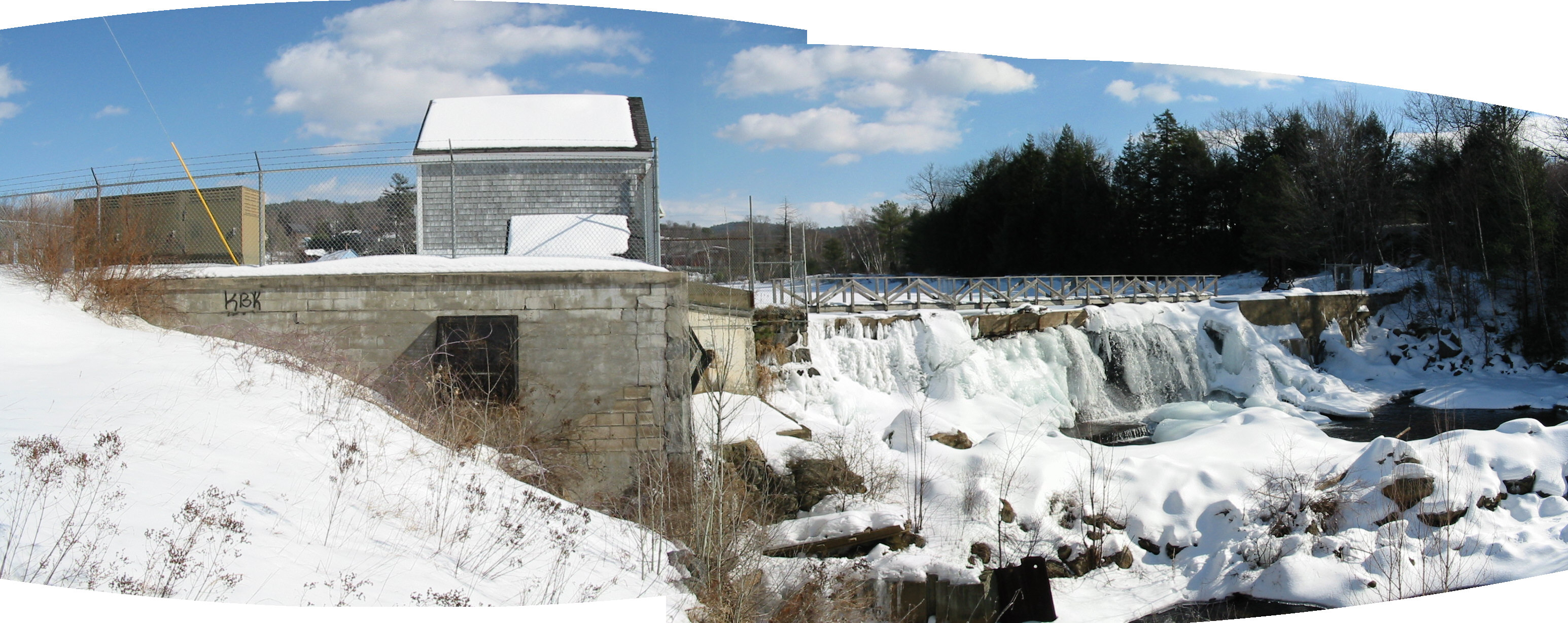

Panorama of powerhouse and spillway looking west. The catwalk spans the spillway and facilitates trash and stoplog removal. It is an excellent canoe catcher!

Powerhouse and spillway looking north.

Celesty and I just measured the vertical distance from the deck to the tailrace training walls. She is designing a beam trolley to lift the turbine in and out of service to avoid paying for a crane each time.

Celeste and Will conferring about worm hole repairs.

The turbine core is being removed from the shop. It was very heavy and the crane was not level. We used the forklift to prevent the boom and turbine from swinging sideways.

Will standing in front of the firmly grounded turbine. We both gave a sigh of relief.

A view of the turbine core and outer shell.

Lifting the outer shell onto the core.

Will guiding the outer shell onto the inner core.

We have just finished loading the Hydrolec Unit onto a double drop trailer for its trip to N.H. The combined weight of the inner core and outer shell was the heaviest pick our little crane ever made!

The next morning, the good folks at Ashland Electric Light, courtesy of Mr. Lee Nichols, Director helped us unload the turbine and gantry pieces. The double drop trailer was too low to drive up to the powerhouse so Mr. Nichols loaded it into a dump truck.

The Hydrolec unit being lifted over the power house security fence.

The 18 inch tall by 28 foot long, gantry, I-Beam is being dragged down the dirt access road to the powerhouse. Lee Nichols, Will and Joel Cooper supervise the operation.

The assorted pieces of the gantry (columns, and cross beams) are being trucked to the powerhouse.

End of a long day!!! The 18 inch I-beam at the powerhouse. The top of the Hydrolec can be seen behind the truck.

One of the gantry H frames being lifted up by a local fork lift truck. Once they were stood up vertically and in place, Will through drilled the concrete floor and bolted the frames down.

The two frames are bolted in place. The 18 inch I-beam has been freshly primed. It is hanging from two 3-ton chain falls.

The new construction trailer in .

This view shows how far out the new beam is cantilevered in order for the turbine to be rolled out to its final location.

Celesty is lifting the beam off the powerhouse deck.

Will and Celesty lifting the beam higher.

The three of us have transferred the load from the chain falls to the chain cum-a-longs in order to pull the beam closer to the H-frames.

My sweetheart, Carol, is staining the powerhouse.

The gang of four!!! Carol, Celeste, Dave and Will at the end of another long day.

The 5 ton chainfall being rigged onto the 18 inch beam by Celeste and Will.

Celesty installing cables and turnbuckles to stabilize the H-frames.

New chainfall rigged into place

New chainfall in place.

The rebuilt turbine sitting next to the security fence on oak cribbing.

The turbine has been jacked up with three railroad jacks. Caterpillar, machinery rollers have been placed beneath the oak cribbing and the unit has been rolled across the deck beneath the lifting gantry. Will used two cable cum-a-longs in series to pull the unit across the floor.

Panoramic view of powerhouse, lake, gantry, dam, turbine and construction trailer.

A close up view of the turbine resting on the oak cribbing. Just visible beneath the cribbing is the caterpillar machinery rollers.

Will has lifted the T/G set from its cribbing and is flipping it from a vertical to a horizontal position.

More flipping!

We forgot to cover the electrical conduit. It filled with rainwater. You can see the water draining from the conduit. We thoroughly drained it, baked it out and meggered the leads to ground.

Will covering the chainfall up so we can go home. It was Laconia Bike Week and the annual motorcycle races at Loudon. There were more motorcycles on Route 93 than cars!!

I’ve “gone to the dogs”!!!!!! King Tut, Queen Cleo and I relaxing at the end of another long day.